B-AACC

| Data Sharing |

|

| Alarm & Event Management |

|

| Scheduling |

|

| Device & Network Management |

|

Industry 4.0 is transforming traditional manufacturing comprising of industrial control Systems and the industrial internet of things (I-IoT), giving birth to the concept of smart factories. As a result, industrial OEMs are rapidly launching new connected products to stay competitive.

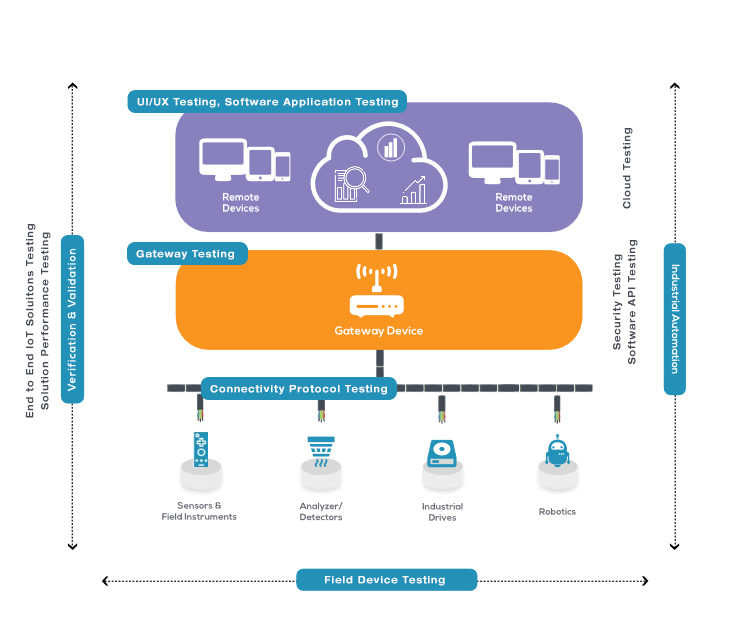

Testing such industrial products and systems requires specialized technology expertise that industrial OEMs may not always have in-house. PTL’s deep domain expertise and capabilities in industrial-IoT and control systems engineering help deliver seamless solutions and products.

Whether you are a process control or factory automation systems manufacturer, PTL is your partner for delivering bug free and stable products.

Smart industry networks are dominated by various choices of communication protocols. Most industrial and SCADA systems use either proprietary communication protocols such as DeviceNet, Profibus, TCNet, TOS Line etc. or open standard protocols such as MODBUS TCP, Ethernet/IP, OPC/UA, HART and wireless HART for device communication. In addition, the IoT revolution demands embedding internet protocols like Haystack, MQTT, CoAP on the north bound side where the data is exposed to the cloud over the internet.

PTL is a pioneer in providing testing solutions across all such communication protocols.

Product managers must build feature plans and create product requirement documents which forms the basis for product development. Despite following good processes during a typical product life cycle, many products fail in the field, increasing the cost of maintenance with a risk of diminishing the OEMs brand value and market reputation. To minimize such risks, OEMs must engage an independent third party to validate and test their products and solutions.

PTL with its deep domain expertise examines product plans and documents which development teams may overlook eventually causing failures in the field.

There is an increasing trend on account of the industry 4.0 evolution in the smart factories segment to host centralized systems over the cloud enabling monitoring and control of multiple industrial networks from a centralized location. This causes several challenges for solution providers to meet stringent performance requirements.

In case of standalone products like SCADA, PLC’s, industrial controllers, metering systems over various fieldbus protocols becomes a challenge to meet performance requirements even though product functionalities may be working properly.

PTL’s deep domain knowledge and ability to form a simulated environment to validate performance along with its expertise in test automation, creates a compelling option for OEMs to successfully manage product/solution performance challenges.

Industry 4.0 demands many different systems and solutions to work in an integrated manner. Such independent systems are integrated with each other using application programming interfaces (API’s) which must meet expectations with respect to functionality, performance, reliability and security of the overall system.

PTL’s rich experience in working with such smart and complex IoT enabled solutions using advanced technologies, helps OEMs to arrest defects and drawbacks while deploying APIs in the integrated environment.

Today’s factory management systems demand solutions comprising of various software components all developed through a partner eco system and to be integrated to form the wider solution.

Smart factory deployments must deal with integration of many third-party systems calling for OEMs to work together. This kind of integrated environment demands an efficient effort in the form of integration testing.

PTL can act as the third eye to make smart factory solutions reliable, robust and flawless.

Cloud based smart factory solutions need a secure gateway to communicate data and information from industrial networks to cloud networks over the internet. This need is driving the growth of industrial gateway product lines which have the capability to communicate data from standard south bound protocols like DeviceNet, Profibus, TCNet, TOS Line, MODBUS TCP, Ethernet/IP, OPC/UA, HART to north bound protocols over the internet like Haystack, MQTT, CoAP etc.

Edge gateways are rapidly gaining market share with high compute powered intelligent applications like in-built data analytics, rule engines, control algorithms. Edge Gateways have the provision for seamless integration with 3rd party systems.

PTL has in-depth strength and experience in testing various complex multiprotocol gateway applications including data security and data analytics. OEMs can leverage PTL’s capabilities to shorten time to market and detect product failures before they hit the market.

Factory management systems rely on intelligent algorithms to increase the operation efficiency, overall energy efficiency, safety and security for human beings. The data gathered from various sources is analyzed using machine learning and deep lLearning applications. This data is stored in different databases like MongoDB, InfluxDB etc. and is further processed for analysis to allow for controlling actions. This brings challenges to solution providers and OEMs in terms of validating such intelligent systems.

PTL’s smart factory domain experts, data scientists and machine learning experts carry out verification and validation of such systems and help OEMs and solution providers improve time to market with stable bug free products.

HMI and SCADA systems are an integral part of any industrial system and manufacturing plant. HMI and SCADA software platforms are involved in driving many operational and business-related decisions. Hence, the UI/UX testing and HMI/SCADA functionality testing becomes one of most the important aspects before being deployed in the industrial network.

PTL’s rich domain expertise and capability of HMI/SCADA testing helps you meet the industrial expectations and gives a seamless user experience.

Smart factory management solutions comprise of cloud-based management systems, on premise management systems, edge gateways, HMIs, SCADA systems, PLCs, application specific controllers, sensors. All these systems are categorized either software systems or embedded systems. Stringent performance testing, load testing, stress testing, regression testing, API testing must be carried out on these systems before field deployment. Automated testing using scripting language like python or selenium like tools becomes important to achieve time to market and cost optimization.

PTL’s smart factory domain experts make use of test automation frameworks like softTAF and other available frameworks and tools to build automated testing environment to help OEMs achieve their business goals.

| Data Sharing |

|

| Alarm & Event Management |

|

| Scheduling |

|

| Device & Network Management |

|

| Data Sharing |

|

| Alarm & Event Management |

|

| Scheduling |

|

| Device & Network Management |

|

| Data Sharing |

|

| Alarm & Event Management |

|

| Scheduling |

|

| Trending |

|

| Device & Network Management |

|

| Data Sharing |

|

| Alarm & Event Management |

|

| Scheduling |

|

| Trending |

|

| Device & Network Management |

|

| Data Sharing |

|

| Alarm & Event Management |

|

| Scheduling |

|

| Trending |

|

| Device & Network Management |

|